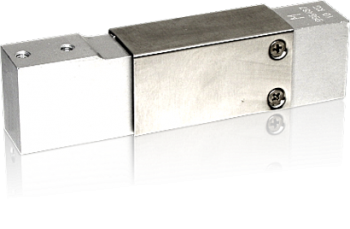

Product Description

The main application for the platform load cell 1040 is in filling and packaging machines. It is the three beam design which gives the 1040 a high natural frequency and low deflection making it particularly resistant to sudden dynamic loads.

For example if you drop a 300g potato from a height of 20 cm into the stainless steel hopper of a linear or multi-head weigher, a typical peak load of up to 10,000g can occur and this may happen millions of times per year. Similar applications can be found in the bagging and filling applications in the medical and pharmaceutical process industries.

The Model 1040 load cell is manufactured using an optimised complex machining process. This ensures that there will be no measurement error when the load is placed off centre, eg in a corner of a platform.

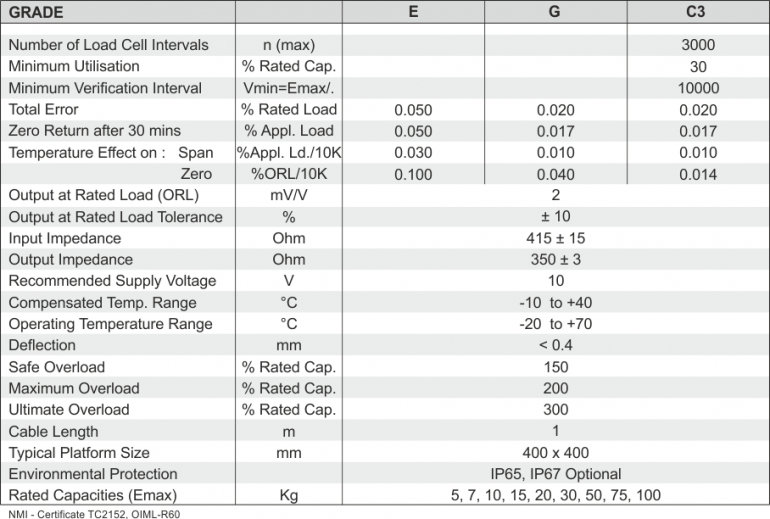

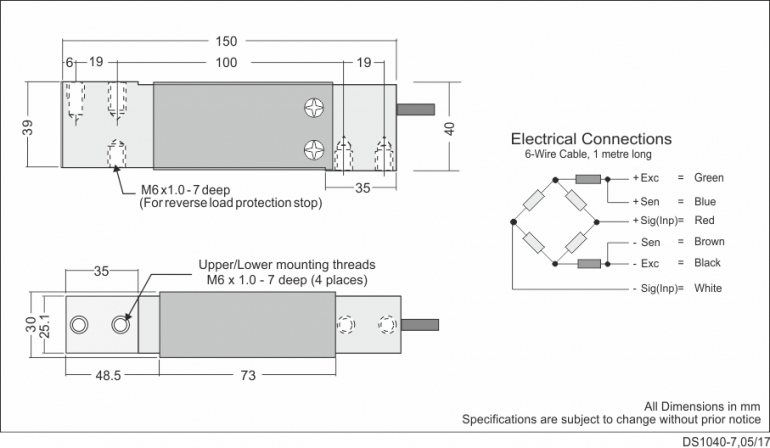

A platform scale can easily be constructed using this load cell. You simply have to mount the load cell between two steel or aluminum plates up to 400 mm square, securing the bottom plate to the threaded holes in the underside of the load cell (cable entry end) and the top plate to the threaded holes on the upper face (opposite cable entry end). The load cell then has to connected to a suitable display or readout.

For additional sealing, the model 1040 can be provided with optional Sylgard protection